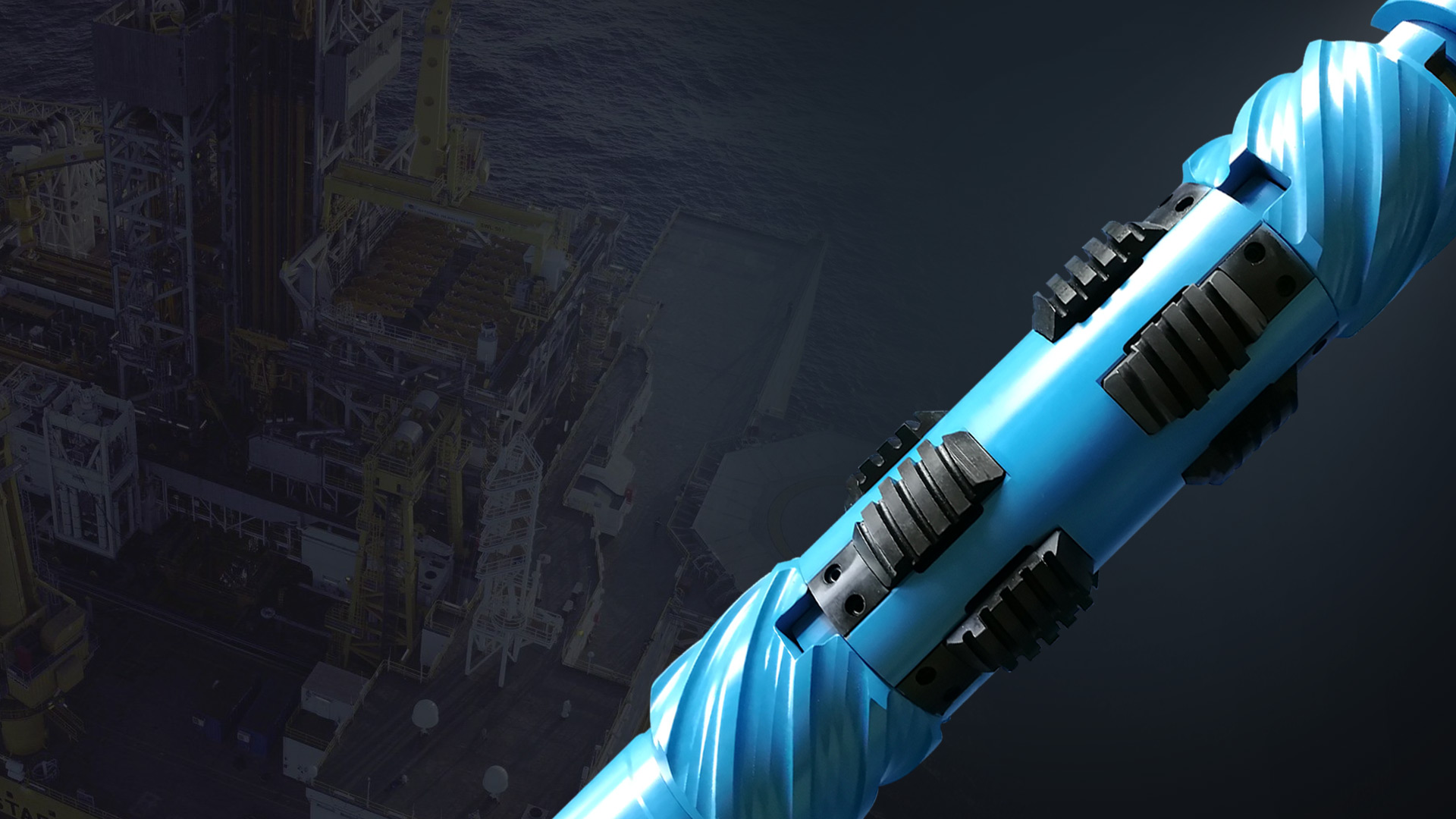

CASING RUNNING TOOLS

CASING RUNNING TOOLS

ULTRASONIC SPRAYING

TORQUE REDUCTION SUB

STABILIZER PROCESSING

MULTI-FUCTION CASING SCRAPER

创造最佳产品,提供最佳服务

EMAIL:info@nsj-drilling.com

TEL:0453-6293088

FAX:0453-6293789

POSTCODE:157013

ADDRESS:No.56 Xingye Road, Mudanjiang City, Heilongjiang, China.

© 2021 HEILONGJIANG NORTH SHUANGJIA DRILLING TOOLS CO., LTD. 黑ICP备16001467号-3