Sleeve ground anchor

Product categories

- Product Description

- Material download

-

- Commodity name: Sleeve ground anchor

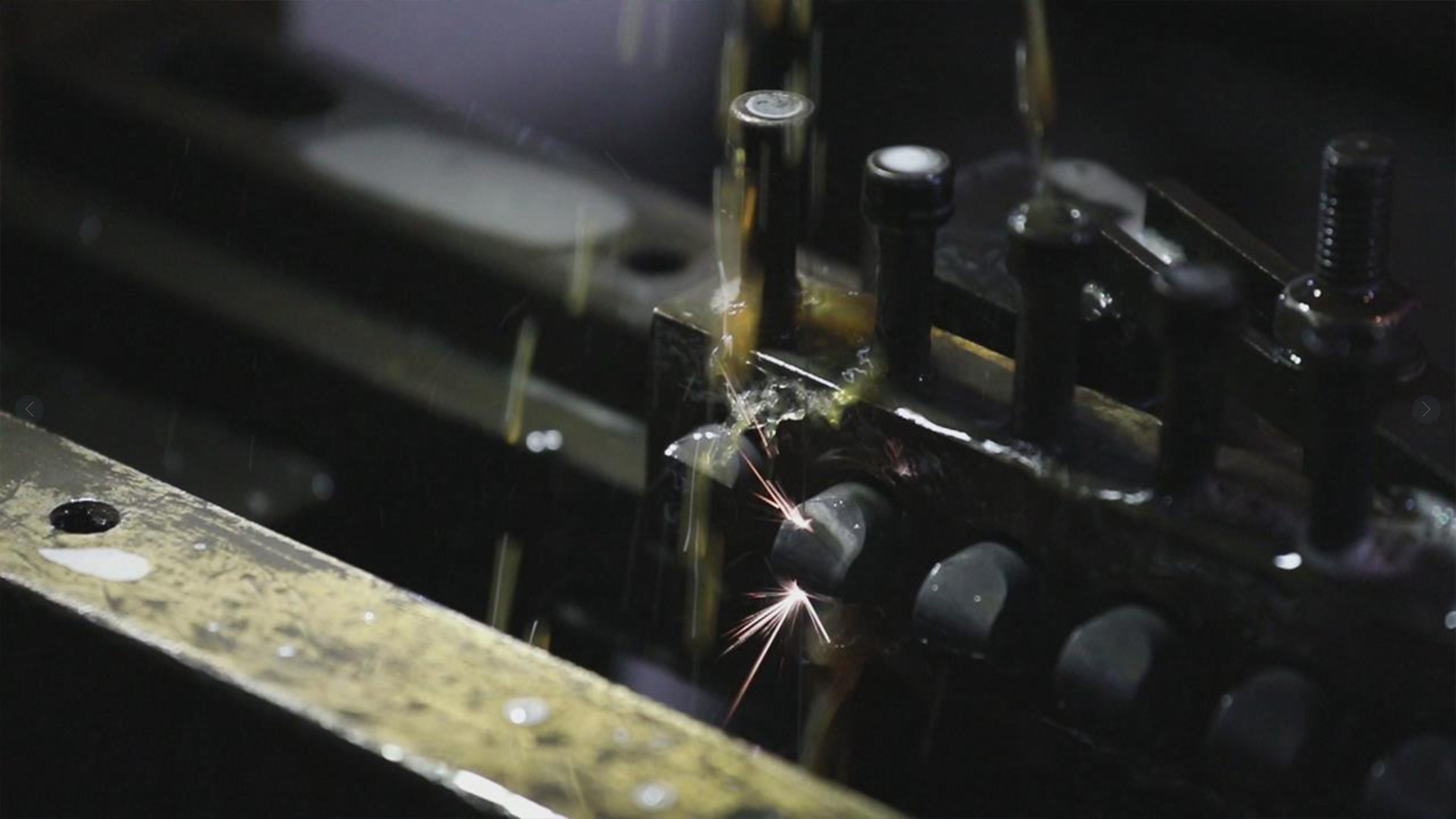

The casing anchor is designed with two levels of anchor claws of different lengths, the shorter upper claw suitable for reduced diameter and hard formation wellbores, and the longer lower claw suitable for loose and enlarged wellbores. During anchoring, the two levels of claws interact automatically; the primary claw opens first during operation, and when its force is insufficient, the secondary claw automatically opens and anchors in conjunction, complementing the primary claw. The anchor claws have a large open diameter, reaching up to 560mm. The tool incorporates a claw locking mechanism to prevent accidental opening during lowering. It integrates a float collar, float shoe, and guide shoe, reducing the cost of the completion string. The two levels of anchor claws are symmetrically distributed along the axial direction at a 90° angle. This design not only improves the strength of the anchor but also enhances its adaptability and reliability, ensuring successful application in shallow loose enlarged diameter formations, deep reduced diameter wellbores, and irregular hard wellbores.

The casing anchor is designed with two levels of anchor claws of different lengths, with the shorter upper claw suitable for reduced diameter and hard formation wellbores, and the longer lower claw suitable for loose and enlarged wellbores. During anchoring, the two levels of claws interact automatically. During operation, the primary claw opens first; when its force is insufficient, the secondary claw automatically opens and anchors, complementing the primary claw. The open diameter of the claws is large, reaching a maximum of 560mm. The tool incorporates a claw locking mechanism to prevent accidental opening during lowering. It integrates a float collar, float shoe, and guide shoe, reducing the cost of the completion string. The two levels of claws are symmetrically distributed along the axial direction at a 90° angle. This design not only improves the strength of the anchor but also enhances its adaptability and reliability, ensuring successful application in shallow loose enlarged diameter formations, deep reduced diameter wellbores, and irregular hard wellbores.

The casing double-level anchor is connected to the bottom of the casing string, directly connected to the casing. After the casing is lowered to the bottom of the well, the pump is started to circulate, and the drilling fluid returns from the circulation hole. Normal cementing and pressure testing are performed. After the rubber plug is pressure tested, it sits on the upper rubber plug of the anchor, and then slowly builds pressure. When the pressure reaches 15-20 MPa, the shear pin is sheared, the anchor rubber plug seat moves down, pushing the central tube and connecting rod assembly, opening the double-level claws, making them anchor to the well wall. Under pressure, the wellhead is pulled to achieve the design tonnage or length, the casing is cemented, and the tensioning of the casing is completed.

Online inquiry

If you are interested in this product, please fill out the following form and send your needs to us, and we will reply to you as soon as possible!

Related Products