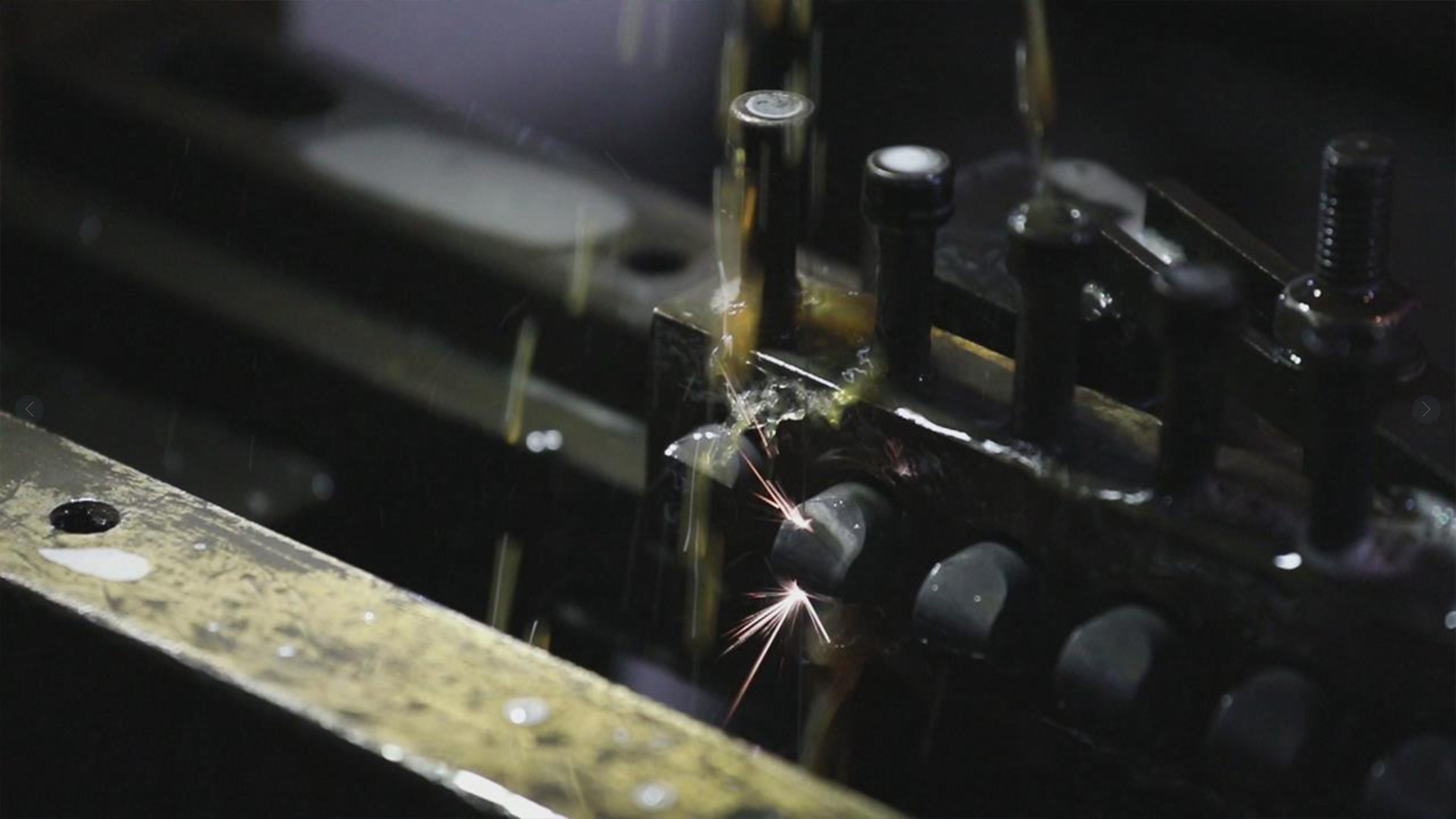

A bottom-hole milling shoe is a tool for milling downhole debris, such as broken drill bits, bit teeth, calipers, casing shoes, drill pipes, drill string connectors, deep-well pump parts, and other dropped objects.

Details >Conical milling shoes are mainly used to repair deformed fish tops or to trim the rolled edges and burrs caused by various tools connecting to the casing during underreaming, as well as to clean mineral crystals and other hard debris remaining on the wellbore wall, in order to restore the diameter. The conical milling shoe consists of a cone and welded YD alloy or inlaid hard alloy, as shown in the figure. The cone has a taper of 30°, and the cone is wing-shaped, with the conical surface of the wing welded with hard alloy. The upper part of the milling shoe is a drill pipe thread, which connects to the drill pipe. The cylinder has a centering block to prevent serious milling of the inner wall of the casing during operation. There are 3-5 water channels along the axial direction, and the main body has straight-through or bypass water eyes from top to bottom to ensure smooth well cleaning. The conical milling shoe relies on the alloy on the cone to mill the protruding casing inner wall and the crystals and other impurities remaining on the casing inner wall. Its cylindrical part plays a centering role, and the milled debris is brought back to the ground by the drilling fluid.

Details >A concave bottom shoe is a tool for grinding downhole dropped objects, such as broken drill bits, roller cones, calipers, casing shoes, drill pipes, drill string connectors, deep well pump parts, and other dropped objects.

Details >EMAIL:info@nsj-drilling.com

TEL:+86 4536293088

FAX:0453-6293789

POSTCODE:157013

ADDRESS:No.56 Xingye Road, Mudanjiang City, Heilongjiang, China.

©2021 Heilongjiang Northern Shuangjia Drilling Machinery Co., Ltd. Hei ICP No. 16001467-3