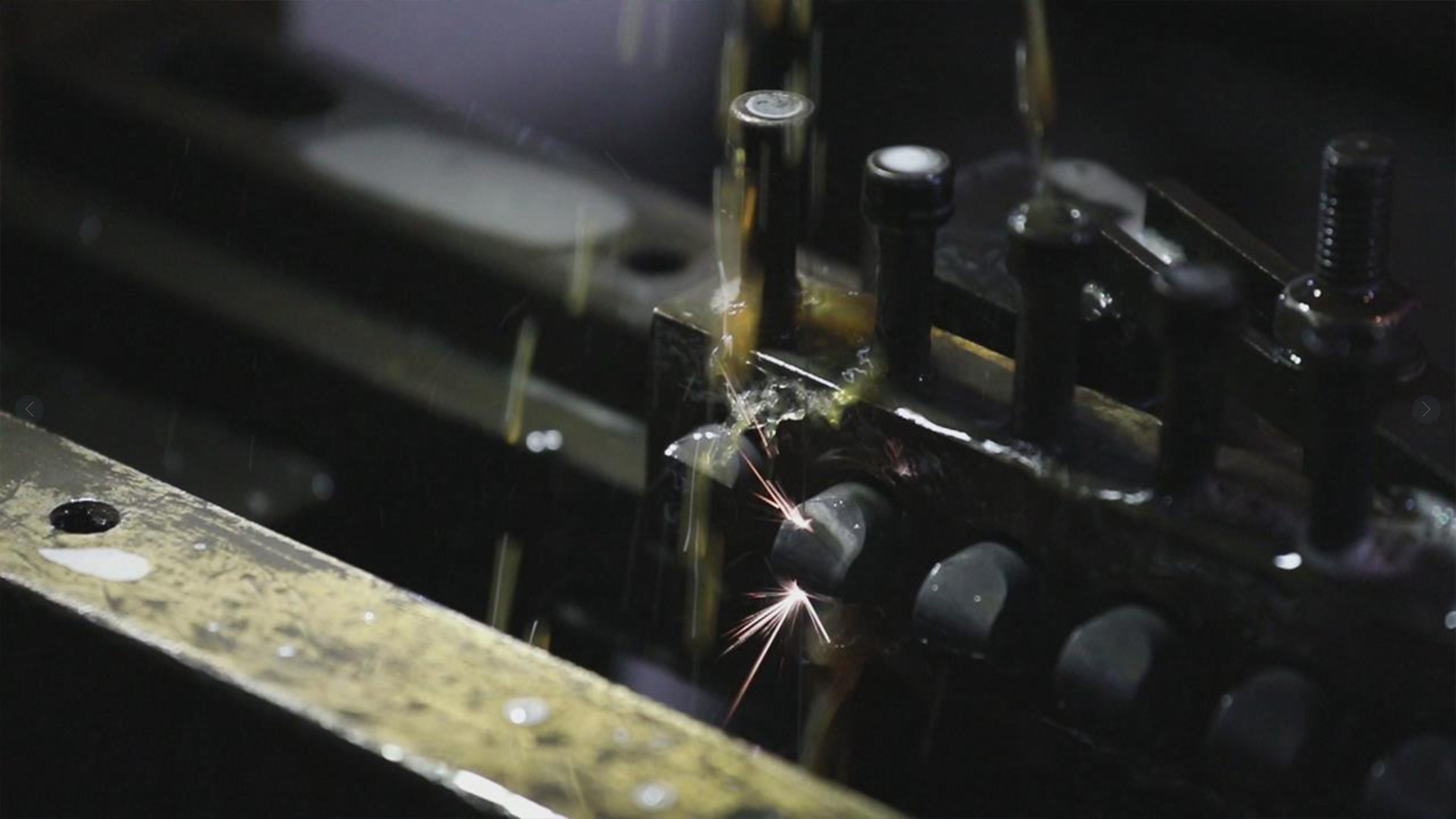

The square drill stem valve, also known as a square drill stem cock or drill stem safety valve, is a manually controlled valve in the drill string circulation system and is one of the effective tools for preventing well blowouts. Square drill stem valves are divided into upper and lower square drill stem valves. The upper square drill stem valve is used between the lower end of the faucet connector and the square drill stem. The lower square drill stem valve is used between the lower end of the square drill stem and the upper end of the drill stem. It can be switched on or off by rotating it 90° with a special wrench according to the instructions.

Details >The tubing swivel valve, also known as a tubing cock, allows drilling fluid to flow freely without pressure drop. This type of valve is installed above the tubing to control wellhead pressure and prevent fluid loss when the tubing is removed.

Details >The full-opening safety valve is a manually operated control valve in the drill string circulation system and is one of the effective tools to prevent blowout. During drilling operations, to prevent serious accidents, the full-opening safety valve should be connected between drill pipes. The full-opening safety valve can be opened or closed by turning it 90° with a special wrench as required. When it is necessary to lift the drill pipe or when the kelly is not lifted, it is best to install a full-opening safety valve as a precaution.

Details >A downhole safety valve is a high-pressure drop, one-way valve. The valve's conical plug reduces the erosive action of the mud on the valve seat, ensuring proper closure. Connected to the drill string, the downhole safety valve protects the swivel, hose, and riser. It can also be used upstream of high-pressure pumps to prevent high-pressure well blowouts. A dedicated release tool keeps the valve in the open position, allowing reverse flow. The release tool is pre-installed in the valve as a component, ready for installation on the drilling rig. When the first blowout signal appears from the well, the safety valve can be quickly installed on the drill string.

Details >FPJ internal blowout preventer

The FPJ inner blowout preventer is a high-pressure drop one-way valve. The valve is sealed with an arrow-shaped valve seal. Under the action of the back-circulation pressure and spring force in the drill string, the arrow-shaped valve quickly closes, cutting off the passage in the drill string and achieving the purpose of preventing blowout in the drill string. It can be kept on the platform for standby or installed between the drill pipe and drill bit after removing the top opening device to prevent high-pressure oil and gas from spraying out from the drill string. A dedicated release tool keeps the valve in a normally open state, allowing reverse flow. The release tool is pre-installed in the valve as a component and prepared on the drilling platform. When the first well blowout signal is detected when the drill pipe is pulled out of the well, the blowout preventer can be quickly installed on the drill string.

Details >Arrow-type check valves (drillstring check valves) are an important type of downhole blowout preventer commonly used in oil and gas drilling and workover operations. They enter the wellbore with the drillstring and, in the event of a kick, well flow, or a stop in positive circulation, the arrow-type check valve quickly closes under the action of back pressure and spring force within the drillstring, blocking the flow path within the drillstring and preventing a blowout.

Details >