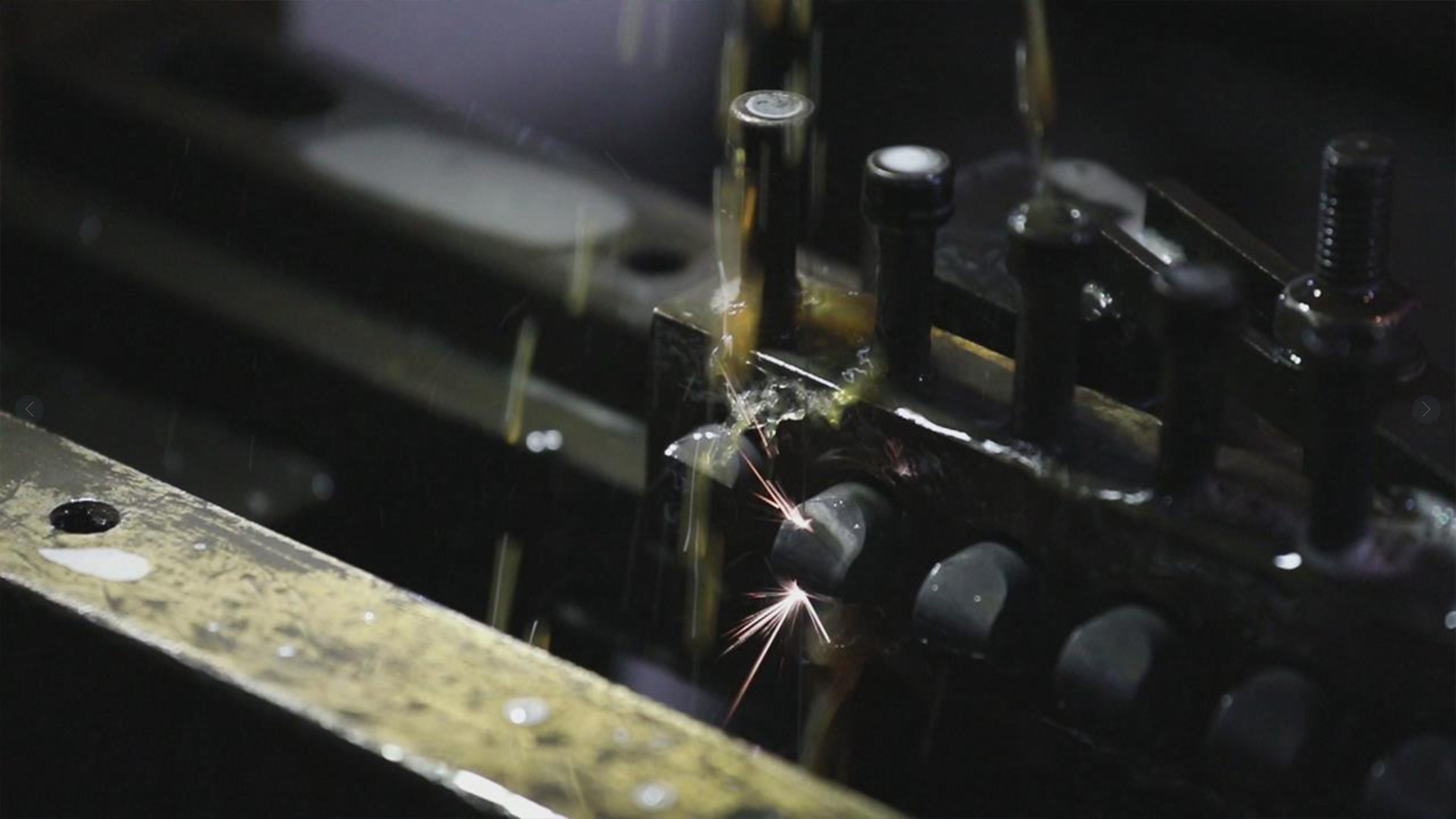

Hydraulic external clamping casing setting device

The hydraulic external clamping top drive casing running device is a device based on a top drive drilling system used for casing running operations. The upper end of the device is connected to the top drive main shaft or displacement compensator, and the top drive can precisely control the upper coupling torque of the casing during casing running operations. A hydraulic structure drives the clamping jaw to reset/open, thereby loosening/clamping the casing to transmit rotation and lifting loads, completing the actions of upper coupling, lifting and lowering the casing, and rotating the casing during running. The device uses a self-sealing leather cup to seal the casing, allowing for simultaneous mud injection during casing running operations, and allowing for timely mud circulation when the casing is stuck, reducing or avoiding complex accidents, while also having a casing pressure test function.

Details >Hydraulic inner-card sleeve device

The top drive casing running system is a new casing running technology. In view of the limitations of conventional casing running operations, our company has developed a safer and more efficient internal-locking casing running device. This technology can take advantage of all the advantages of top drive drilling, and can simultaneously perform rotation, lifting, and circulation of mud during casing running, maximizing the guarantee that the casing can be normally lowered to the bottom of the well. It greatly improves the success rate, operational safety, and operational efficiency of casing running.

Details >Mechanical external card sleeve device

The top drive casing running system is a new technology for running casing. In casing running operations, the most important thing is to safely lower the casing to the bottom of the well. Our company's EMCRT external card mechanical casing running device can complete the work of engaging, lifting, lowering, rotating, and circulating, maximizing the guarantee that the casing can be normally lowered to the bottom of the well, greatly improving the success rate, safety, and efficiency of casing running operations.

Details >Top drive floating buffer is an important tool in drilling engineering. It is suitable for oil, natural gas and geological exploration drilling process, mainly used in the vertical drilling operation of deviated and straight wells and rigs equipped with top drive. It can effectively extend the life of bearings and gears in the top drive rotary box.

Details >Top drive kelly cocks (IBOP) can be divided into two types: top drive upper kelly cock and top drive lower kelly cock. They are control valves used with the top drive system and are usually connected in series on the top drive drilling rig. The valve uses a highly reliable metal-to-metal seal and can withstand high pressure from both the upper and lower directions. Its working pressure can reach 10,000 psi or 15,000 psi. If a well kick is detected, the top drive upper kelly cock can be remotely closed, and the top drive lower kelly cock can be manually closed. The top drive slip mechanism is an auxiliary mechanism for controlling the opening and closing of the top drive upper kelly cock. It works with other mechanisms of the drilling rig and can be operated to control the opening and closing of the top drive upper kelly cock at any height on the derrick driller's console. The valve cavity and parts have undergone special anti-corrosion treatment, extending their service life.

Details >The function of the top drive single guide rail is to provide vertical sliding guidance for the top drive, playing a supporting role to facilitate the connection of the kelly and the centering of the casing during casing running. It also offsets the reaction torque from the rotating drill string during drilling, transmitting the reaction torque to the derrick base instead of the derrick itself. All parts of the top drive guide rail produced by our factory are made of high-quality structural steel and alloy structural steel. The connecting lugs are heat-treated, with high tensile strength and good weldability. Its function is to drive the drill string rotation and provide reaction torque strength. It provides a track for the top drive unit to move up and down during normal drilling and rig-up/rig-down operations.

Details >