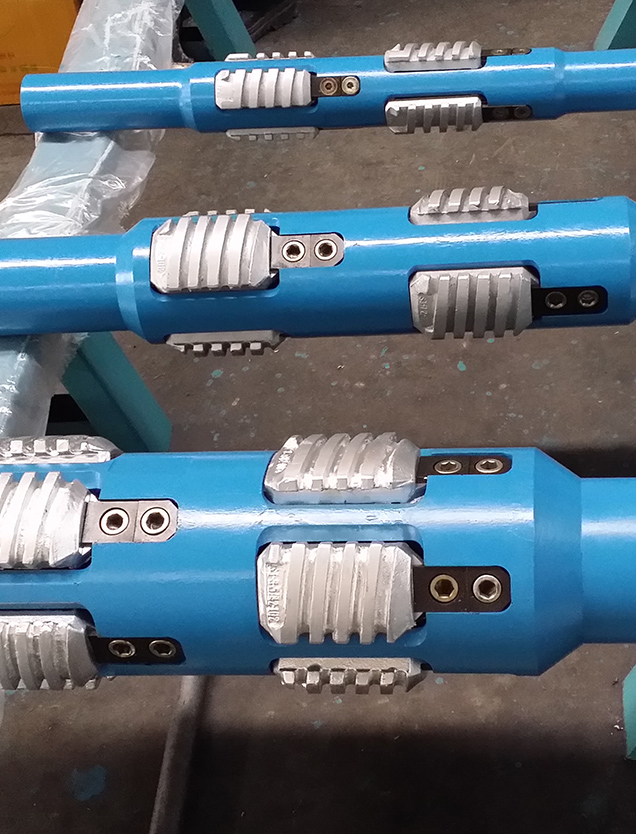

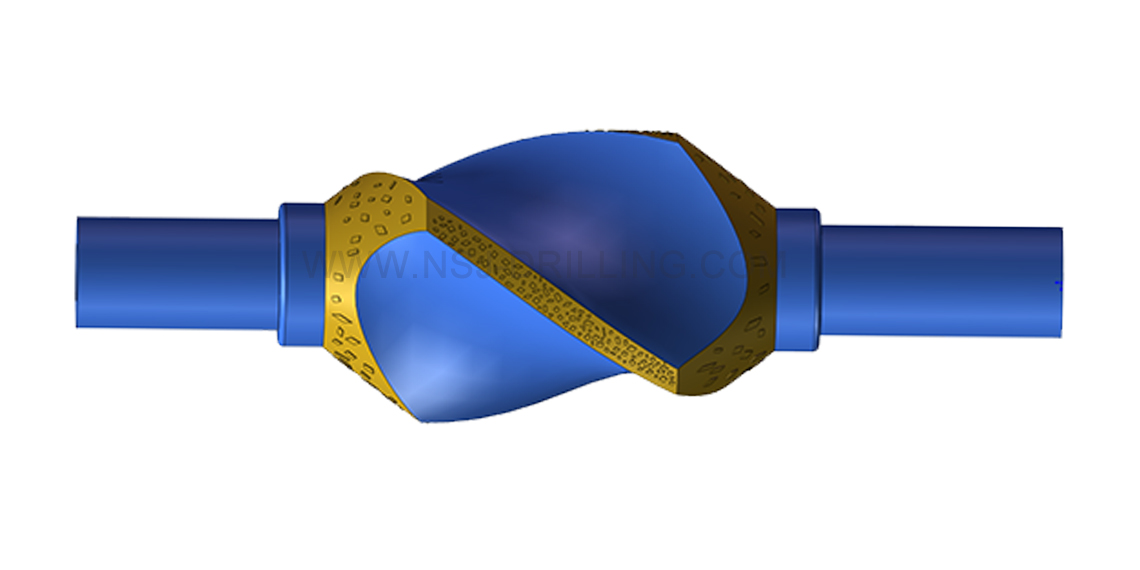

STRING MILL

PRODUCTS

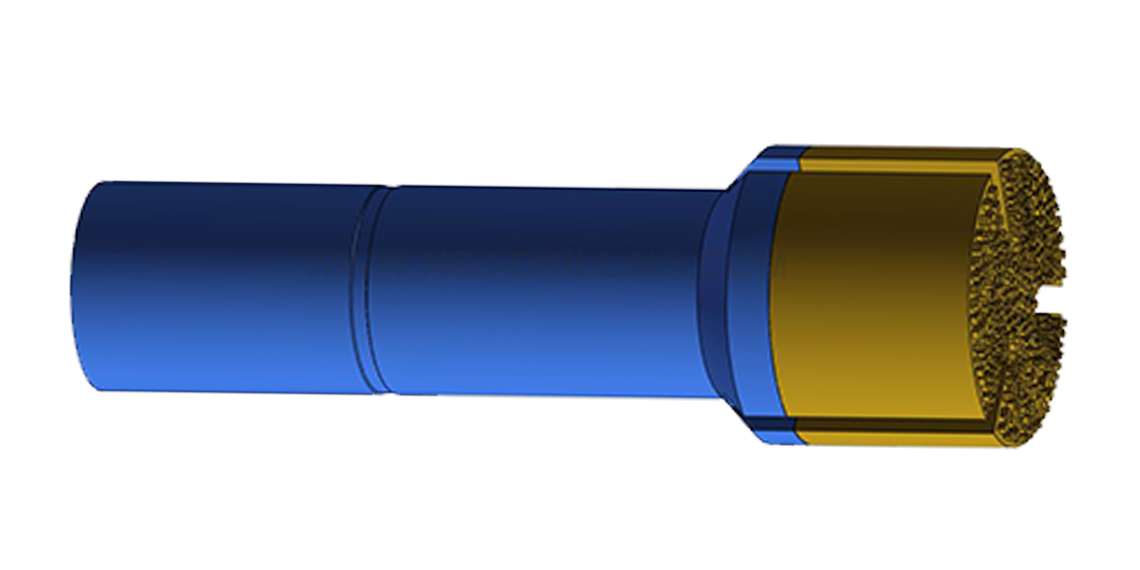

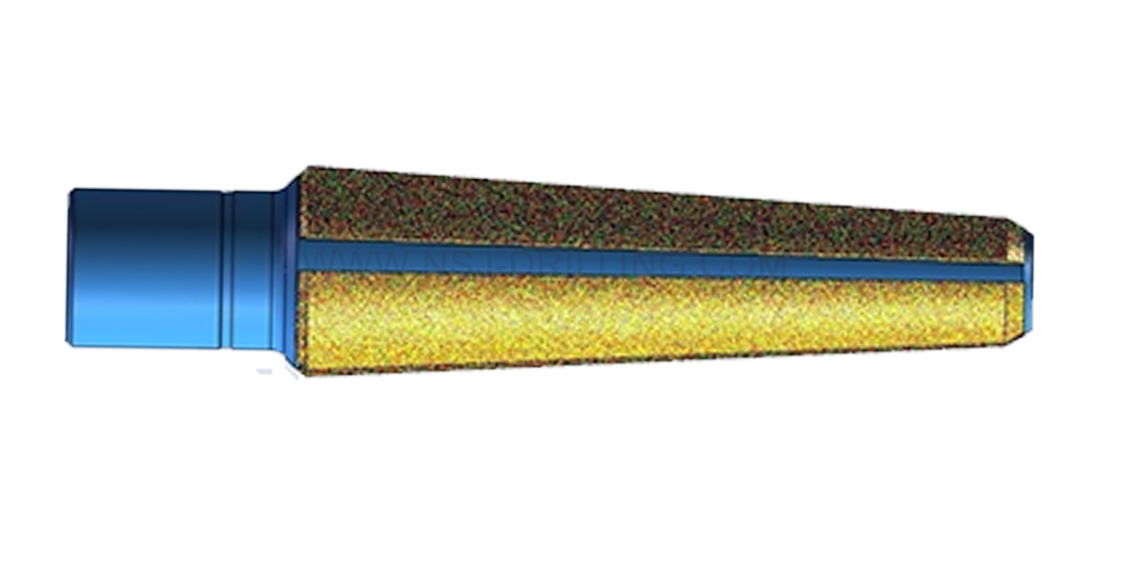

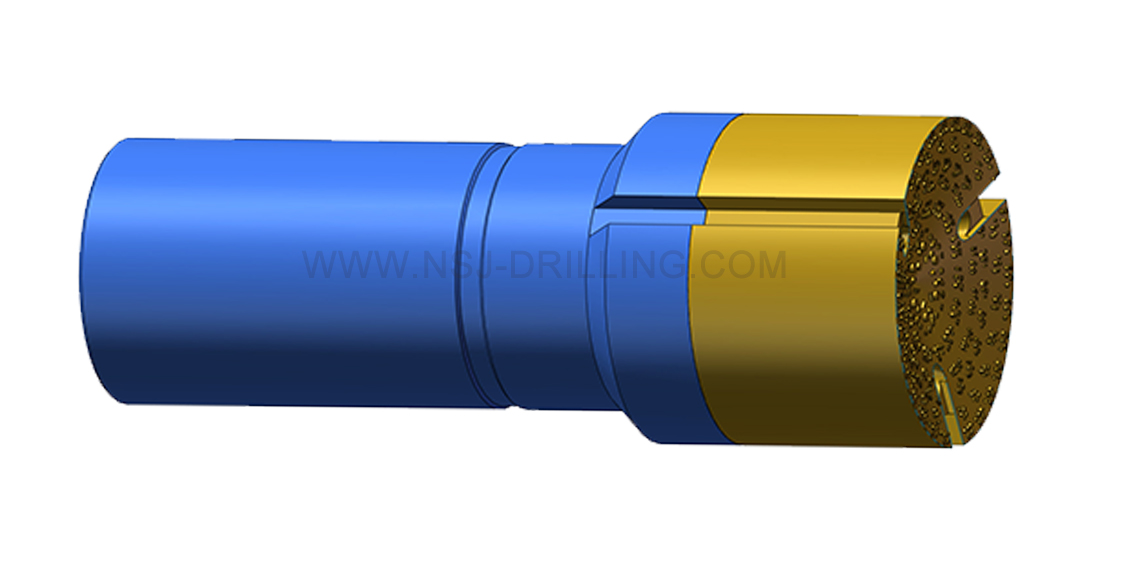

String mill is used to trim casing that is slightly bent or slightly deformed, to trim sections that suffer resistance while running down the liner, and to trim casing in broken sections where the fracture is not much misaligned. When the dislocation of the upper and lower casing fracture is not large, the fracture can be repaired straight to facilitate the next operation,the essence of string mill is lengthen the cylindrical part of the taper mill, When the deformation section of the casing is grinding with a taper mill, and the other tool is still unable to pass smoothly, a string mill can be used. Its grinding effect is from the radial direction of the casing grinding, can increase the straightness of the casing.

Inquiry

If you are interested in this product, please fill out the form below and send us your needs, and we will reply to you as soon as possible!

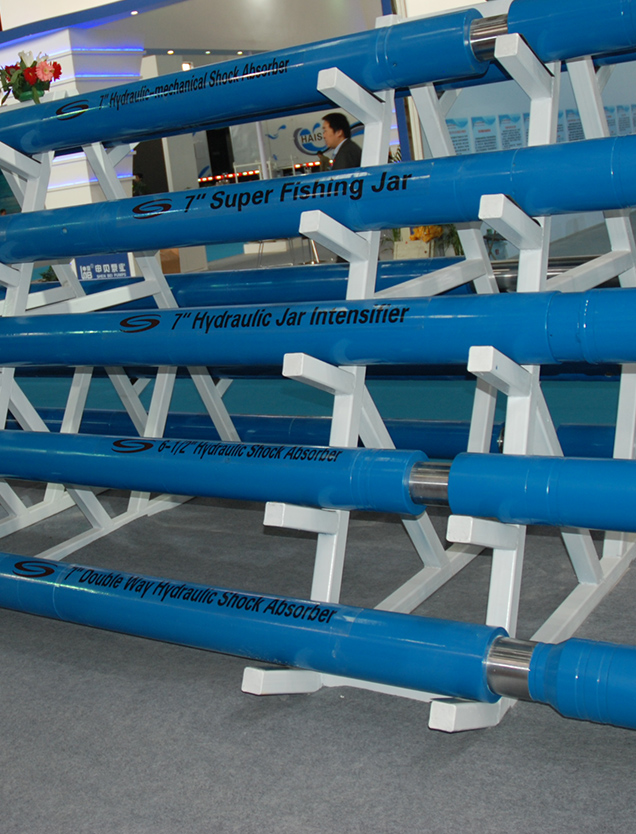

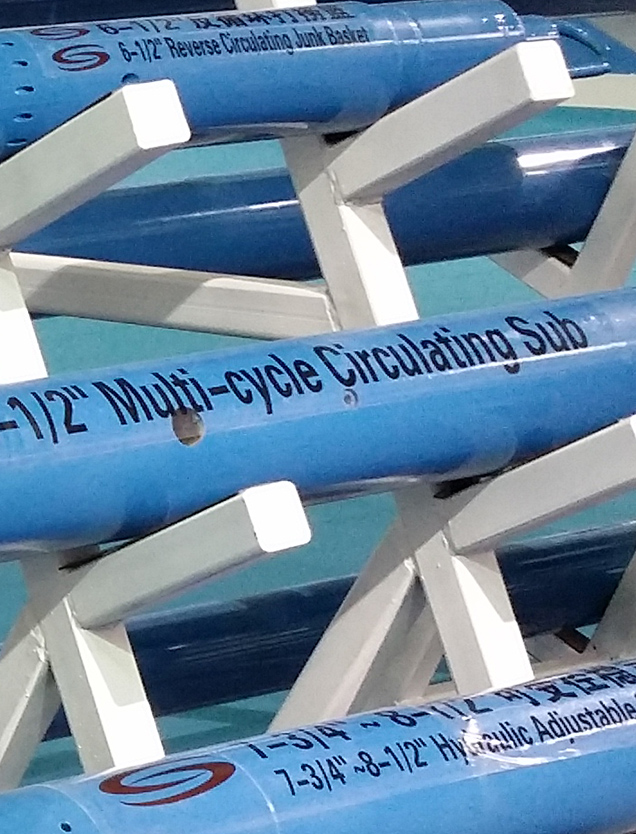

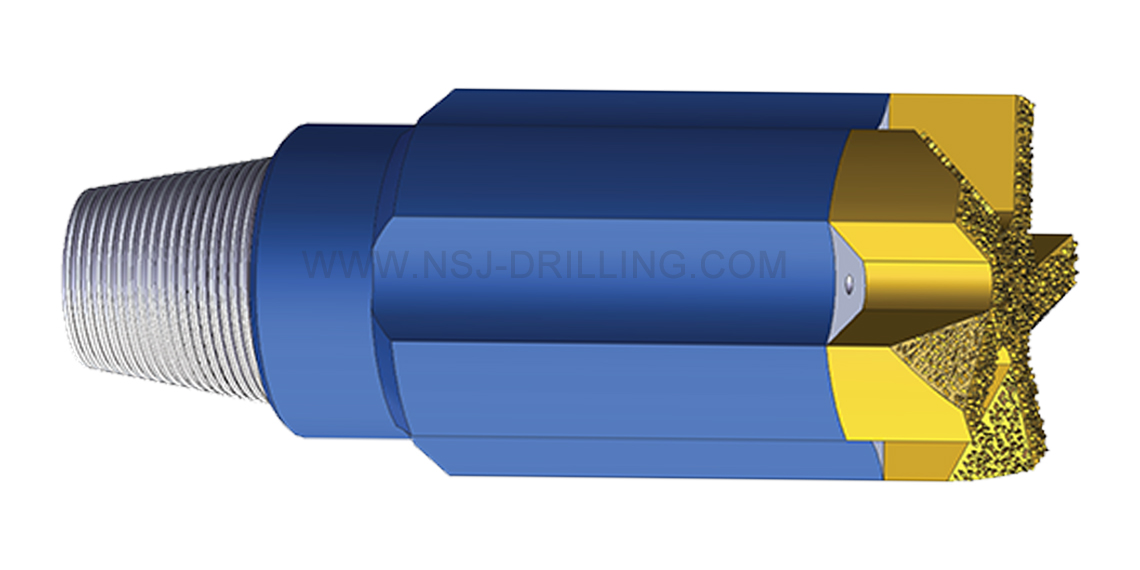

Releated Products

EMAIL:info@nsj-drilling.com

TEL:0453-6293088

FAX:0453-6293789

POSTCODE:157013

ADDRESS:No.56 Xingye Road, Mudanjiang City, Heilongjiang, China.

© 2021 HEILONGJIANG NORTH SHUANGJIA DRILLING TOOLS CO., LTD. 黑ICP备16001467号-3