Search

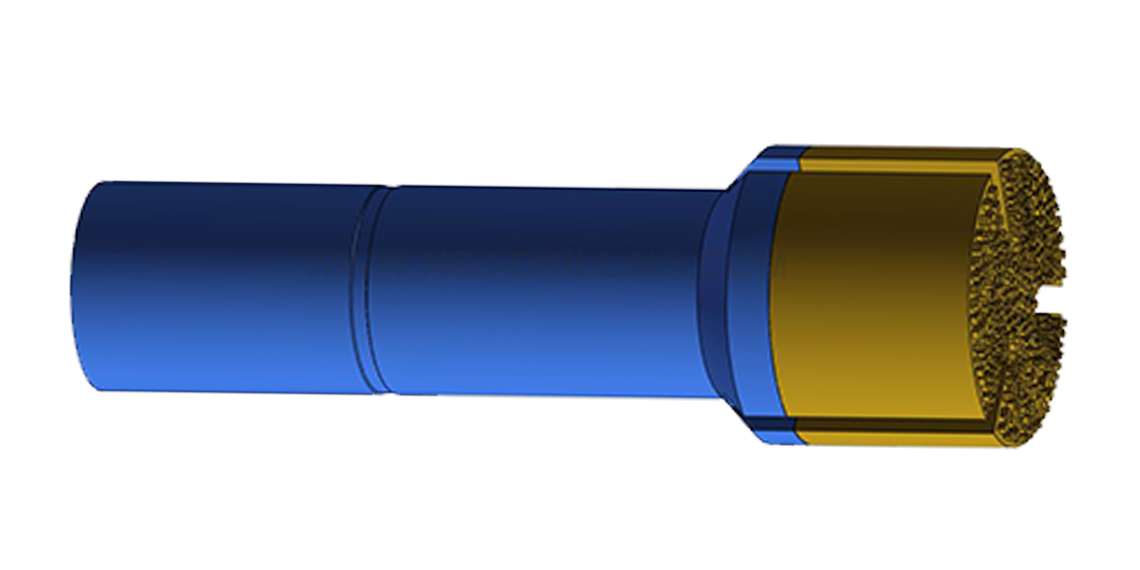

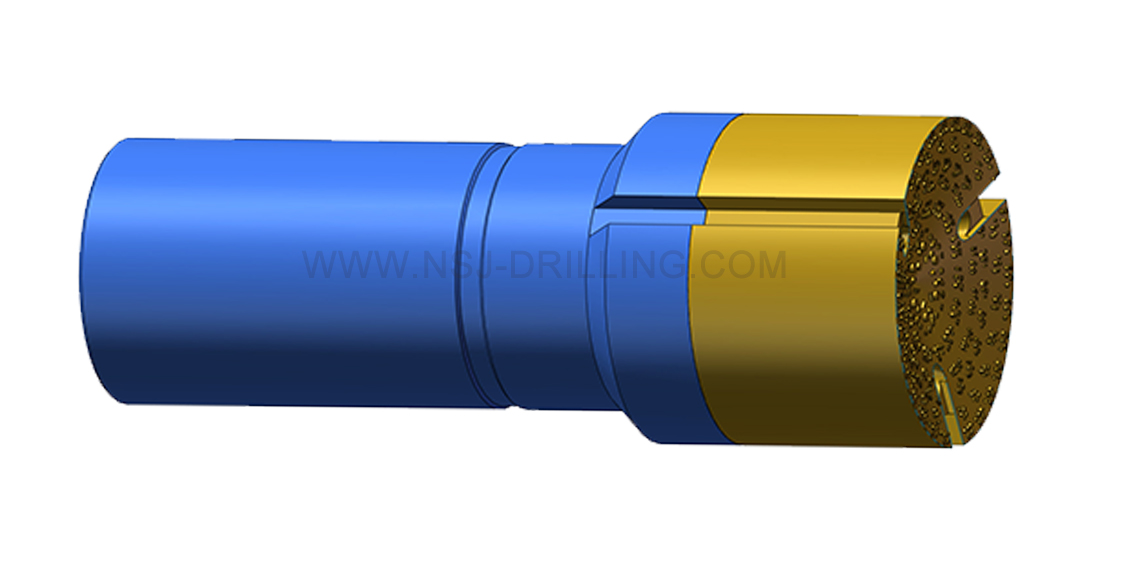

FLAT BOTTOM JUNK MILL

Flat bottom junk mill is a kind of tool for milling the fishes, such as bits, cone, cutter gauge, slip elements, swivel wash pipes, subs, parts of deep-well pump.etc. Flat bottom junk mill is composed of shoe body and wear - resistant alloy. The shoe body is composed of two cylinders; the upper part of the small cylinder is a connection thread, according to the customer's requirements, both pin and box threads are available. The large cylinder has tanks on the bottom and sides, There are mud circulation holes in the bottom water tank, YD alloy or other wear-resistant materials are piled up between the tanks. Flat bottom junk mill rely on the YD alloy and wear-resistant material on the bottom of the surfacing, under the action of drilling pressure, enter and grind the fishes, wear debris with circulation wash out of the ground.

More

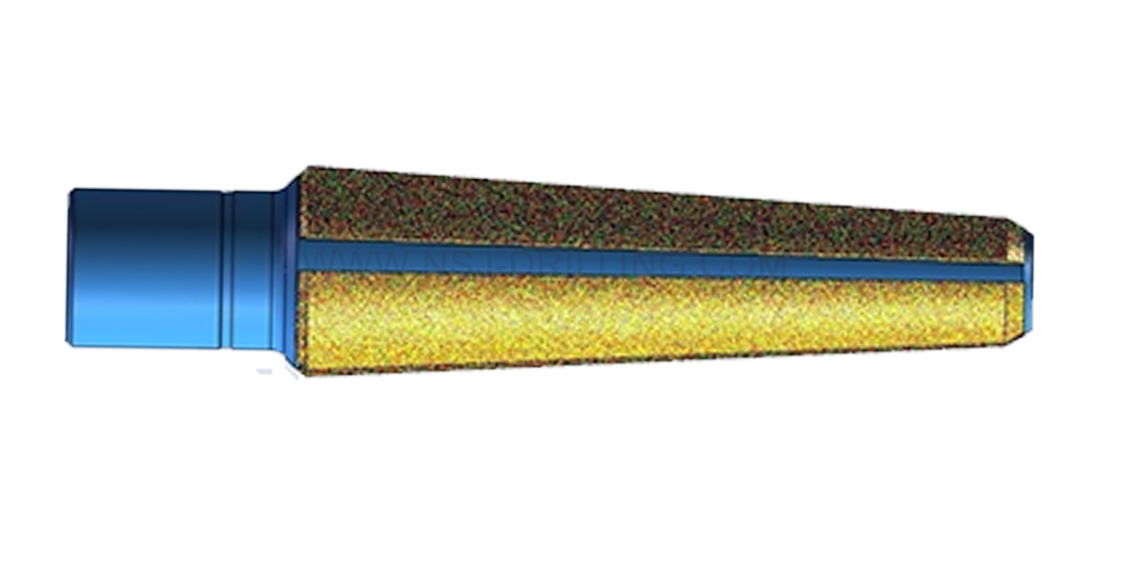

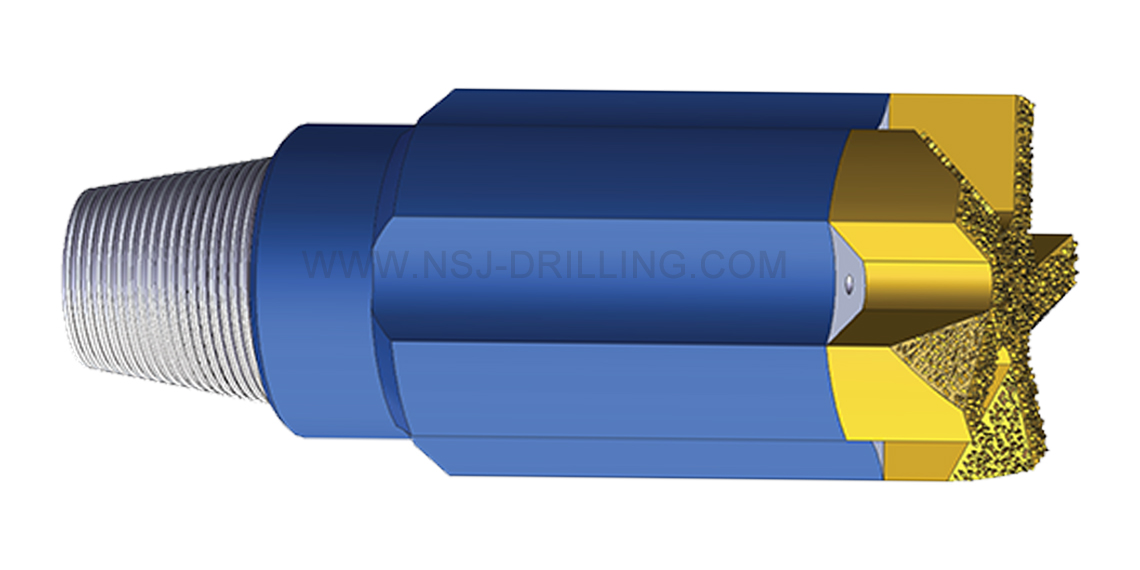

TAPER MILL

The taper mill are mainly used to repair the deformed fish top or trim the curling of the casing at the butt hoop of various tools and the burrs and flaring caused by perforation during the drilling process, and to clean up the mineral crystallization and other hard sundries trapped on the shaft wall, so as to restore the size. Conical shoes are composed of conical body and YD alloy surfacing or insert welding hard alloy, as shown in the figure. The taper of the cone is 30°, the cone is wing like, and the surface of the cone of the wing is welded with carbide. The upper part of the shoe is a drill pipe thread, connected to the drill pipe, and the cylinder has a centering block to prevent severe milling of the casing wall during the operation. There are 3-5 flume along the axial direction, and the body has straight-through or bypassing water holes from top to bottom to ensure smooth well cleaning. The taper mill are by the alloy on the cone milling protruding casing wall and stranded in the casing wall crystals and other impurities. The cylinder section acts as a stabilizer, and the milling debris is carried back to the surface by the well cleaning fluid.

More

CONCAVE MILL

More

ECONOMILL

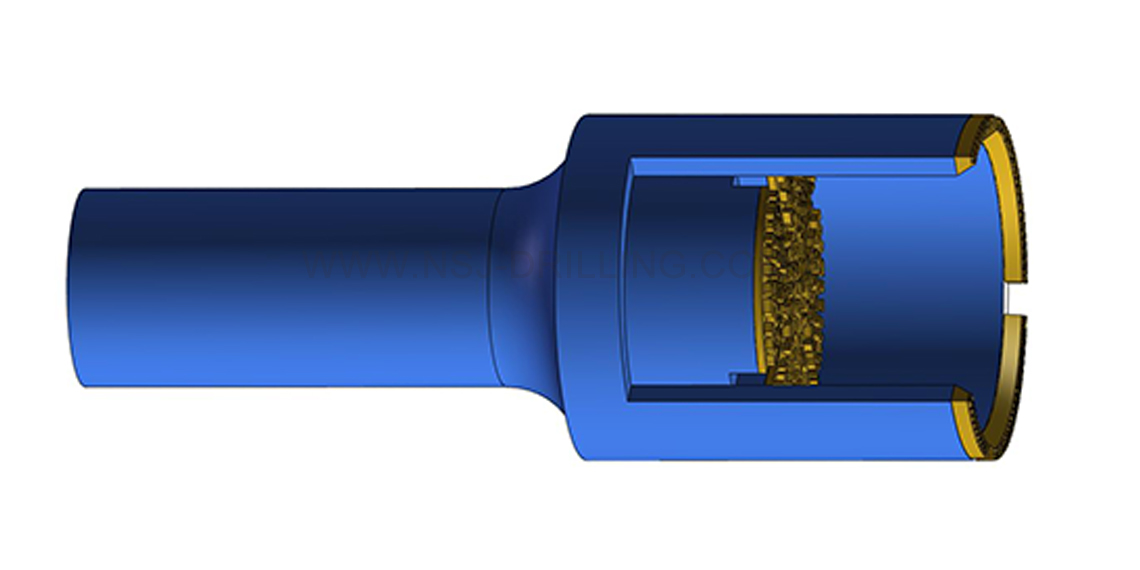

Economill is a kind of tool for grinding the falling objects. Such as grinding bit, cone, drift, slip teeth, washpipe, sub, deep well pump accessories, and other falling objects. As the structure is shown in the figure, it is composed of body and carbon tungsten alloy. The body is composed of two sections of cylinder, the upper part of the small cylinder is a connection thread, the connection thread can be made into pin thread or box thread according to user's requirement. The bottom and side of the large cylinder have a water groove, the bottom of the water groove is opened with a mud circulation hole, YD alloy or other wear-resistant materials between the water groove.

More

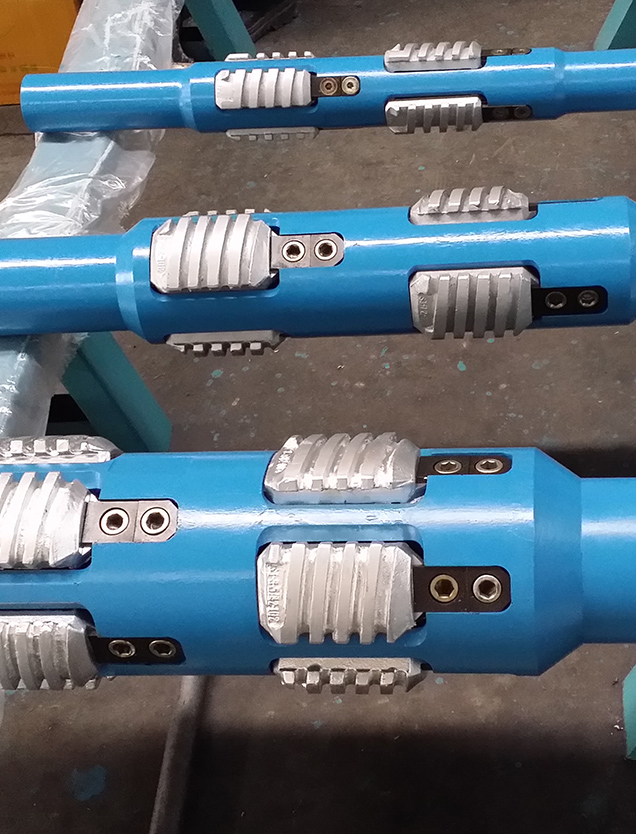

BLADED MILL

Blade junk mill is a tool for grinding fallen objects in wells. Such as grinding drill bits, cones, drift, slips, flushing pipes, drill tool joints, deep well pump accessories and other fallen objects, because the blade can prevent the fishes from being slanted. It is composed of a joint and wear-resistant alloy or alloy button. The body is equipped with the blade to prevent abrasion deviation when the fish is milled. The blade junk mill relying on the YD alloy protruding from the bottom surface and under the action of drilling pressure eat and grind the fallen objects, and the wear debris is brought out of the ground with the circulating well flushing fluid.

More

STRING MILL

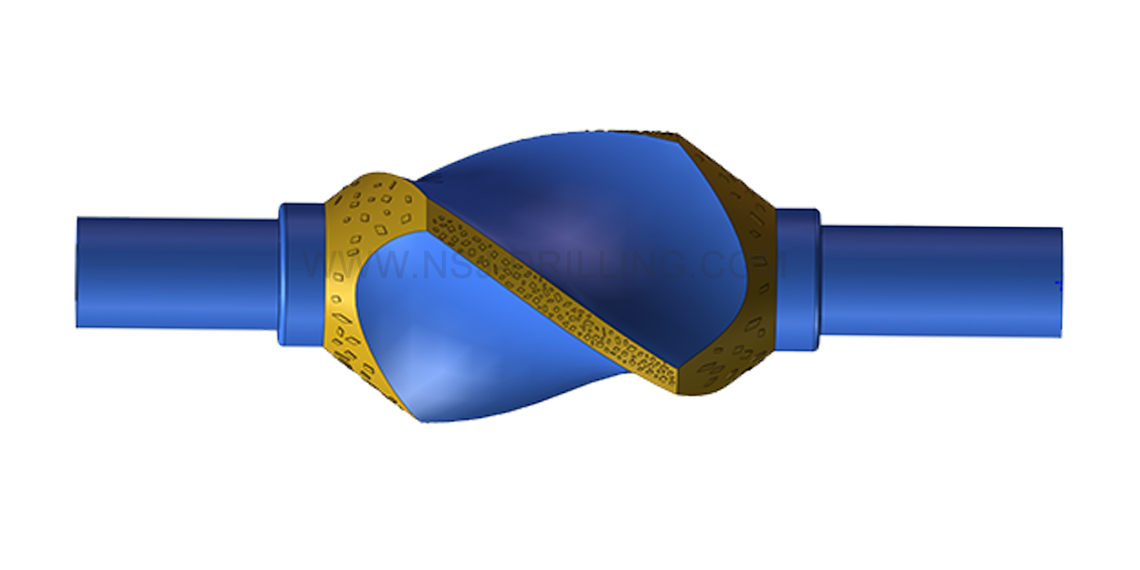

String mill is used to trim casing that is slightly bent or slightly deformed, to trim sections that suffer resistance while running down the liner, and to trim casing in broken sections where the fracture is not much misaligned. When the dislocation of the upper and lower casing fracture is not large, the fracture can be repaired straight to facilitate the next operation,the essence of string mill is lengthen the cylindrical part of the taper mill, When the deformation section of the casing is grinding with a taper mill, and the other tool is still unable to pass smoothly, a string mill can be used. Its grinding effect is from the radial direction of the casing grinding, can increase the straightness of the casing.

More

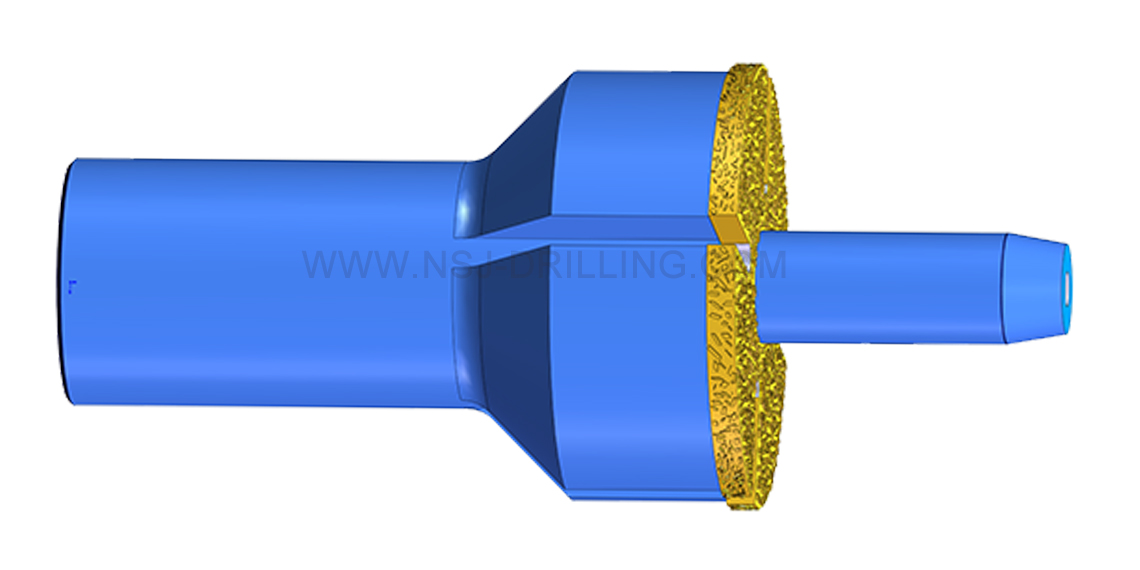

PILOT MILL

The pilot mill shoes is used to mill the fish which have inner bore and instability and shake in the down well, such as drill pipe, drill collar, tubing etc. The pilot mill shoes is made up of mill shoe body and pilot cone, as the following picture. The upper part of the mill shoe body is inner thread, the lower part is cylinder whose diameter is bigger. Add YD alloy and anti-abrasive material on the back plane of pilot cone and mill shoe body. The pilot cone has the effect of leading and fixing the top of the fish. And there are 2-4 water crossing grooves on the back plane of the mill shoe body to make sure it can circulate unblocked. The pilot mill shoes locate the fish by the cone which is entered into the fish, and then rotate with the drilling tool, the mill shoes welded with YD alloy grind the fish.

More

SKIRTED MILL

The skirt junk mill has a skirt, so it can cover the fishes in the skirt to ensure that the fish is always placed in the grinding range of the junk mill, and the bottom cutting teeth are used to grind the fish. This kind of milling shoe can not only mill the annular space by the skirt, but also grind the top of the fish, and use it to grind various swaying pipes and rods.

More

Previous page

1

Next page

EMAIL:info@nsj-drilling.com

TEL:0453-6293088

FAX:0453-6293789

POSTCODE:157013

ADDRESS:No.56 Xingye Road, Mudanjiang City, Heilongjiang, China.

© 2021 HEILONGJIANG NORTH SHUANGJIA DRILLING TOOLS CO., LTD. 黑ICP备16001467号-3